Inspection

Capabilities

As an AS9100 – 2016 certified company, we have established robust process and workflow procedures that enable us to ensure the delivery of 100% high-quality products. Our products not only conform to the required standards but also come with complete traceability, meeting the benchmarks of world-class quality.

To ensure our products’ quality, our fully equipped quality department carries out complete validation before delivering them to our customers.

our process

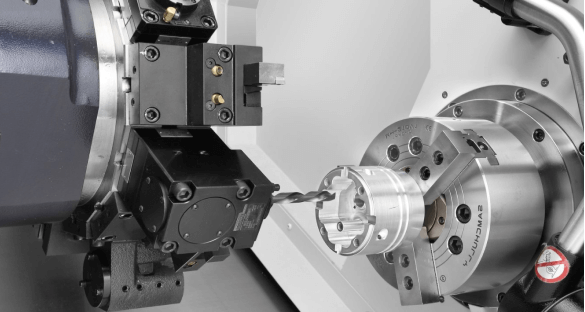

Manufacturing

We obtain the customer-specific requirements using Supplier Quality Manual (SQM) or Master Purchase Agreement (MPA). After accepting the order, a Controlled copy of the Drawing is ballooned, covering all necessary dimensions, material features, notes, etc. This results in a document carrying all the pre-production information.

We conduct First Article Inspection (FAI) in strict compliance with Customer Specified Requirements (CSR) as per AS 9102 or other Specified Requirements communicated by our Business Development, Production, and PPC teams. This ensures that our FAI process meets all the necessary standards and guidelines set by our customers.

Raw materials are procured based on the required grades, such as aluminium, copper, stainless steel, and brass. Non-Confirming Products (NCPs) are rejected, while approved batches go through production to create the First Article.

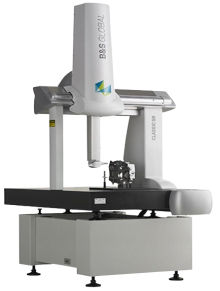

The crafted articles undergo the “Foreign Object Debreeze” (FOD) segment to remove all minute foreign particles. QA engineers then use standard measuring tools and a visual test to verify the First Article, followed by testing it against the engineering blueprint on a coordinate measuring machine (CMM).

After customer approval, the final batch is produced in accordance with the Customer Specified Requirement (CSR). If Surface Treatment (ST) is necessary, it will be outsourced to a customer-approved source and undergo incoming QA before proceeding further.

Quality Control

At Apsis, our team of dedicated Quality Heads, Engineers, and Inspectors utilize state-of-the-art machinery to compare our products against acceptance criteria and uphold exceptional quality standards. We once again conduct the First Article Inspection (FAI) in strict compliance with Customer Specified Requirements (CSR) as per AS 9102. Our rigorous quality check inspections take place at every stage of the production process to ensure top-tier quality.

Once quality control (QC) is complete, we move on to the final stage of the manufacturing process: storage and packaging. We carefully store the product in the packaging room and pack all batch units for dispatch to respective clients.

At Apsis Aerocom, we are committed to leading the charge in building the technology of the future.